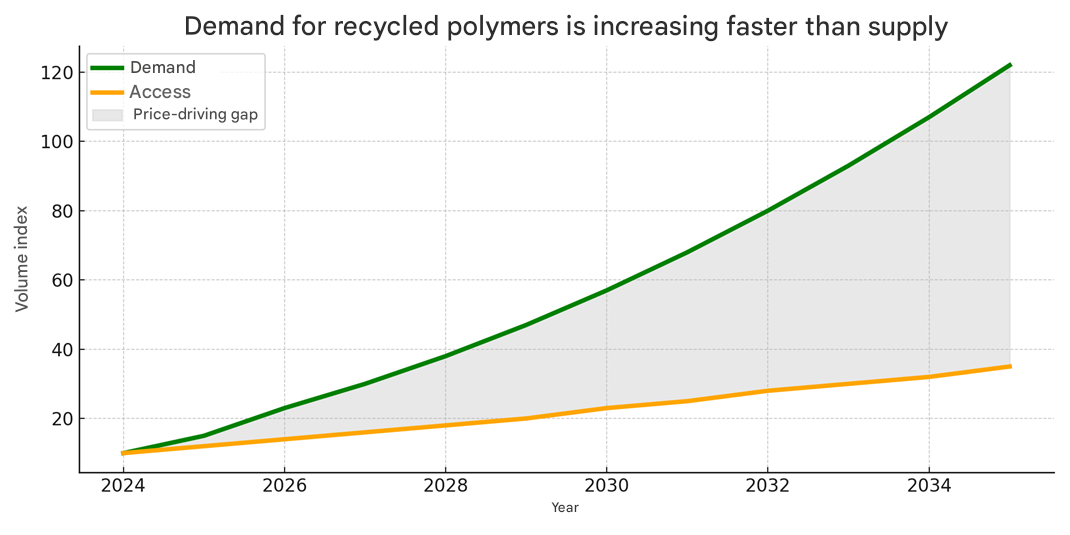

Today we have a global waste problem.

In some years we will have a polymer raw-material problem.

What We Do

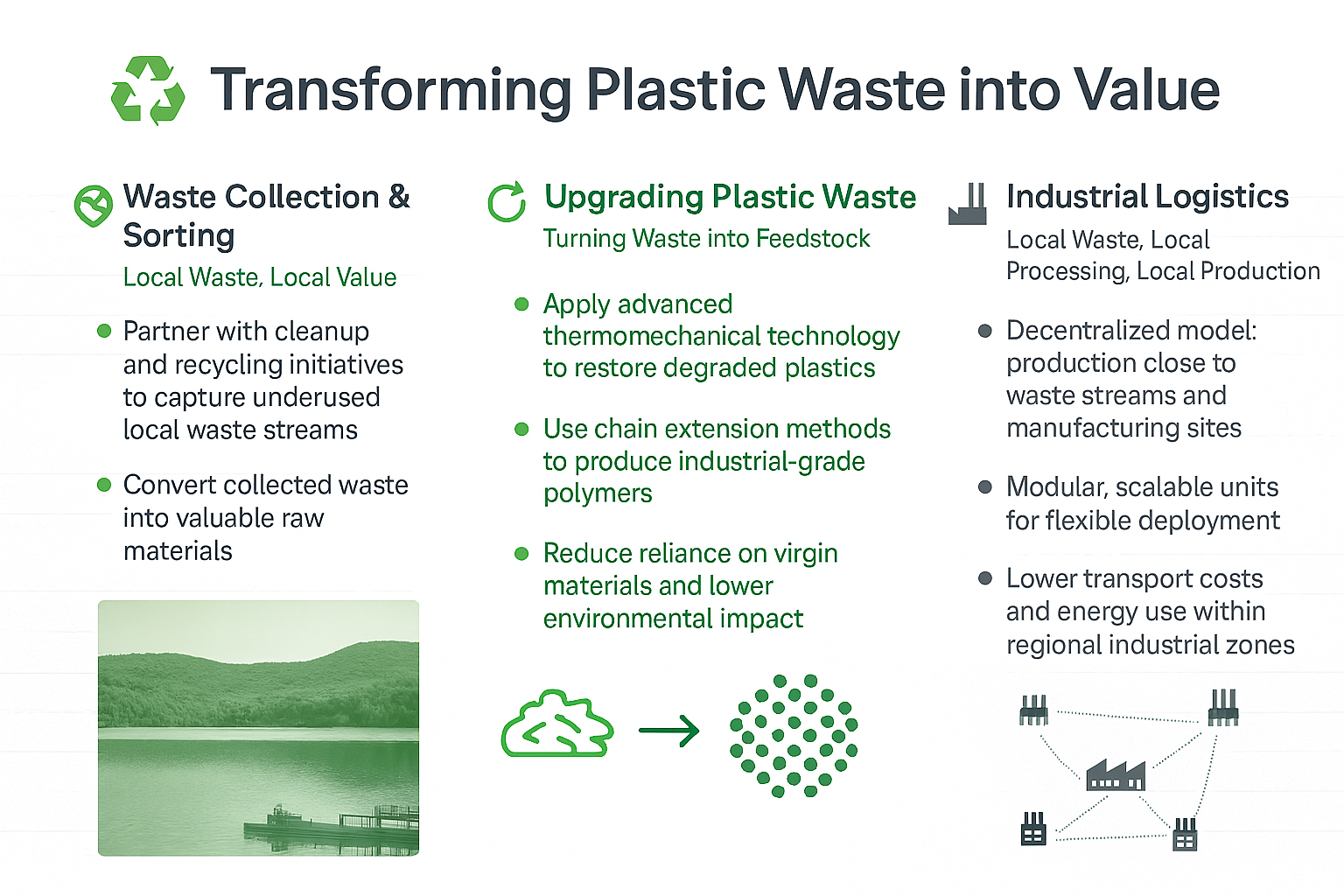

Transforming local waste into high-value polymer raw materials, through industrial innovation.

We collaborate with cleanup and recycling partners to collect and sort degraded plastics from rivers, cities, and industrial waste streams.

Upgrading Plastic Waste

From Waste to Polymer.

Using thermomechanical technology and molecular chain extenders from BASF, we upgrade low-value plastic fractions into new, high-quality polymer pellets ready for industrial use.

Yarn Production & Application

From Polymer to Product

Our polymer compounds are spun into yarn and integrated into new textile products by our industrial partners.

This closes the loop between waste and new material production — locally and at scale.

Turning Waste into Industrial Value

Through decentralized, scalable production systems, we connect the global waste problem with the growing raw-material shortage.

Our approach transforms local waste into industrial value, creating economically viable and replicable solutions that can be implemented anywhere.

Featured on Swedish National Television (SVT Nyheter, 2025).

Partners & Stakeholders

Building an industrial ecosystem through collaboration.

Together, these partners connect waste collection, innovation, and industrial application into one circular process — transforming local waste into industrial value.

Klimatledande Processindustri

Platform for industrial transition.

Connecting business, academia, and the public sector to accelerate fossil-free and circular production.

Research Institutes of Sweden

Polymer and fiber lab partner.

Developing and validating the transformation of degraded plastic into new high-value raw materials.

BASF

Molecular innovation partner.

Providing chain-extending technology to restore polymer quality in thermomechanical recycling.

Lindholmen Science Park

Industrial collaboration hub.

Supporting cross-sector projects linking research, startups, and large-scale industrial implementation.

Everwave GmbH

River cleanup and collection logistics.

Collecting degraded plastics from rivers and waterways to feed circular production systems.

ClimateHero AB

Climate data and LCA partner.

Delivering transparent, science-based assessments that guide improvement and accountability.

Reparell AB

Commercial application partner.

Turning recycled polymer yarn into finished textile products for industrial and professional use.

AIDA

Albanian Investment Development Agency. Government partner for circular industry development.

Our Projects

Reparell Innovation AB develops scalable solutions turning degraded plastic into new industrial feedstock. Each project connects waste, technology, and manufacturing through circular material logic — transforming local waste into global value.

End of Waste

Turning plastic waste into new polymer feedstock.

Upgrading degraded plastics into industrial-grade polymers using thermomechanical recycling and molecular chain extension. Developed in collaboration with BASF, RISE, and Everwave.

Yarn as a Service

From upgraded polymer to global textile production.

Creating spinnable yarns from recycled polymer that fit into existing textile machinery, enabling circular production at scale. Conducted together with Klimatledande Processindustri and RISE.

Local Production Systems

Decentralized and scalable.

Developing small, agile production units close to waste streams and industries to reduce logistics, emissions, and dependency on virgin materials. Collection supported by Everwave in Albania.

Industrial Collaboration

From chemistry to production.

Together with industrial partners, we connect material science, recycling technology, and textile manufacturing to create one circular value chain.

This collaboration bridges lab innovation with real production environments — proving that waste-based materials can perform in modern textile manufacturing.

The Team

Combines experience from textiles, industry, innovation, and scale-up.

Emil Pettersen – Founder

Serial entrepreneur focused on raw-material innovation and industrial circularity. Expert in textile innovation and process scaling. Leads strategy, development, and global partnerships to turn degraded plastics into scalable industrial feedstock.

[Name Redacted] – Co -Founder COO

Experienced operational leader with a background in purchasing, logistics, and digital transformation. Combines extensive experience from large-scale corporate environments and fast-moving tech ventures. Responsible for production management, supplier relations, and the operational scaling of Reparell Innovation’s industrial model across Europe.

[Name Redacted] – Strategy

Former executive in the clean-tech and recycling sector with extensive experience in industrial scale-up, corporate governance, and international expansion. Brings a proven track record from leading a publicly listed environmental technology company through its growth phase.

Katarina Nordström – Dissemination Manager

Experienced innovation strategist with a strong background in industrial collaboration and SME support. Combines more than a decade in Sweden’s science park ecosystem with deep expertise in project management, funding, and communication. Leads Reparell Innovation’s stakeholder engagement and funding strategy, connecting research, industry, and public institutions to drive circular transformation.

Kajsa Jansson – Textile Engineer / Project Manager

Textile engineer specializing in fiber and yarn technology with advanced experience in LCA and CSRD compliance for circular materials. Leads polymer upgrade trials and textile pilot production at Reparell Innovation AB, converting recycled polymers into industrial-grade yarns..

Robert Warper – Co-Founder & Finance & Analysis

Entrepreneur and investor with long-standing experience in company ownership, financial strategy, and sustainable business development. Combines a pragmatic results-driven approach with a strong social commitment, running several community and youth initiatives in partnership with local organizations. At Reparell Innovation AB, Robert ensures financial stability, investor relations, and scalable business models that align profit with long-term responsibility.